Polybutylene Pipe/PB Pipe Extrusion Machine BASELL PB4267

-

Place of OriginShandong, China

-

Brand NameKAIDE

-

CertificationCE; ISO

-

Model NumberKD-PB

-

Minimum Order Quantity1set

-

Price45000-80000USD/SET

-

Packaging Detailssoft film in container

-

Delivery Time60days

-

Payment TermsTT or L/C

-

Supply Ability500sets per year

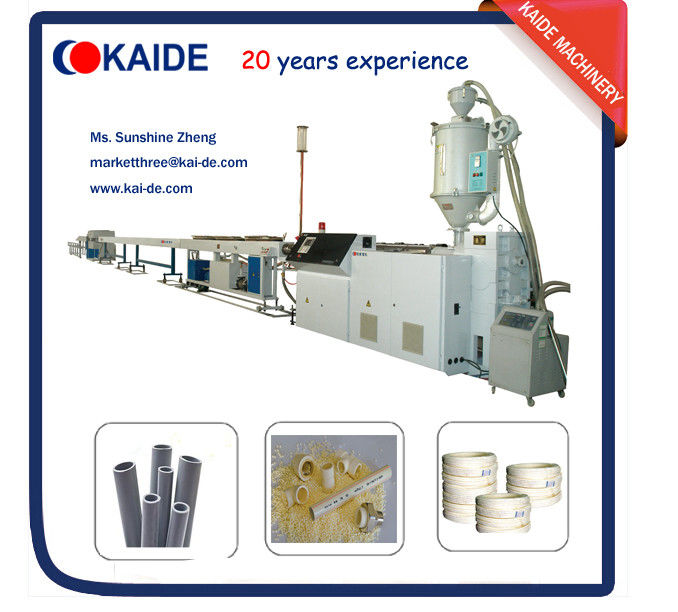

Polybutylene Pipe/PB Pipe Extrusion Machine BASELL PB4267

Polybutylene (PB) Pipe Production Line

![]()

![]()

KAIDE factory has focused on plastic pipe extrusion technology for more than 20 years, especially for high speed pipe production line and multi-layer composite pipe line.

Since 2007, our factory has started manufacturing PB pipe extrusion line. After years development, now we have gained about 80% market share, with most advanced technology and plenty of practical experience.

KAIDE factory is the leading manufacturer for PB pipe extrusion line, such as single layer PB pipe line, and three or five layer PB/EVOH pipe lines.

Main Features of Pipe Production Line:

1) high precise control sytem of the pipe weight per meter is applied in this line. It is used for measuring & calculating and precise control of pipe weight per meter and its extrusion output, to realize the constancy of pipe weight and line running according to set parameters. The application of this system can shorten the start-up time and improve the produced pipe quality, and save raw material.

2) It adopts new designed five-section type screw, special for PB material extrusion, which realizes the stability and plasticizing quality of PB pipe extrusion process. The stability of extrusion pressure is the essential condition to realize high speed production.

3) Our company is the first to overcome the problem, the stable extrusion of PB pipe without melt pump. The application of special designed spiral pressure-storage type die head ensure the high speed and constant pressure extrusion of the pipes.

4) Vacuum calibrators are special designed multi-sheet water bath type, with our company independent intellectual property rights, which realize the even and effective calibrating & cooling effects.

5) It adopts multi-group roller clamping type belt haul-off machine, which completely avoid pipe stretching and deformatiom problems. The pulling speed is high and stable, without any vibrating or slipping problem.

6) SIEMENS PLC control system ensures the high speed synchronous control and reliable operating of the whole prodution line.

7) Added some auxiliary machine, the production line can produce three layer or five layer PB/EVOH oxygen barrier pipe.

Technical Data of Pipe Production Line:

| Line Model | Screw Diameter | L/D | Production Scope | Production Speed | Nominal Power |

| SJ-80 | ф80mm | 30:1 | ф20-32mm | 18m/min | 111KW |

| SJ-65 | ф65mm | 33:1 | ф20-32mm | 15m/min | 74KW |

![]()

![]()

![]()

![]()

![]()