-

Place of OriginShangdong, China

-

Brand NameKAIDE

-

CertificationCE, ISO

-

Model NumberHDPE

-

Minimum Order Quantity1set

-

Price$40000-80000USD

-

Packaging Detailssoft film for sea transport in container

-

Delivery Time60days

-

Payment TermsTT; L/C

-

Supply Ability500 sets per year

Miroduct assembly and sheating pipe making machine

PE Sicon Tube making machine/PE Tube Bundle production line

![]()

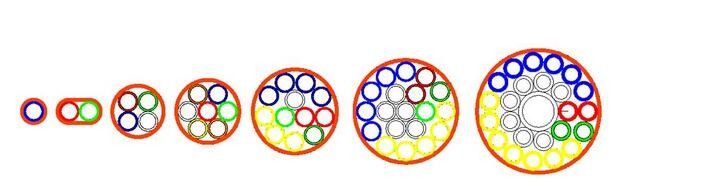

This composite pipe extrusion machine is used to produce the new type communication pipe, called tube bundle. The tube bundle is made by one micro duct or more than one micro duct grouped according to a certain arrangement order with outer sheathing layer. It can hold more conduits in the limited space.

The communication optical cable, cable or the electrical cable into the tube can be pressed into this tube bundle by the cable-pushing machine. At the same time, the strong airflow is forced into tube along the sealed storehouse by the air-compressor. This high-speed airflow forms huge pull which forces the optical cable to move ahead.

This PE tube bundle have the following advantages:

1)widely used

2)Network distribution is quite flexible and convenient

3)Increase the capacity of optical cable, fixed; decrease the friction among the optical cable.

4)Kinds of function

5)Safe and dependable tube system

6)Much more easier to operate, easy to maintain or replace the inner old optical cable.

7)Better physical performance

8)Longer lifespan

Micro tube size and tube bundle information:

|

Item No. |

Outer Diameter (mm) |

Inner diameter (mm) |

Thickness (mm) |

Direct Installation Tube Bundle (Tube number) |

Direct bury Tube Bundle (Tube number) |

|

1 |

5.0 |

3.5 |

0.75 |

1; 2; 4; 7; 12; 19; 24; 27; Outer layer thickness: 1.7mm |

1; 2; 4; 7; 12; 19; 24; 27; Outer layer thickness: 3.4mm |

|

2 |

7.0 |

3.5 |

1.75 |

|

|

|

3 |

7.0 |

5.5 |

0.75 |

|

|

|

4 |

8.0 |

6.0 |

1.0 |

|

|

|

5 |

10.0 |

8.0 |

1.0 |

1; 2; 4; 7; Outer layer thickness: 1.7mm |

1;2;4;7; Outer layer thickness: 3.4mm |

|

6 |

12.0 |

8.0 |

2.0 |

|

|

|

7 |

12.0 |

10.0 |

1.0 |

1;2;4;7; Outer layer thickness: 1.7mm |

1;2;4;7; Outer layer thickness: 3.4mm |

|

8 |

14.0 |

12.0 |

1.0 |

|

|

|

9 |

14.0 |

10.0 |

2.0 |

|

|

|

10 |

16.0 |

12.0 |

2.0 |

|

|

|

11 |

16.0 |

14.0 |

1.0 |

|

![]()

![]()

![]()

![]()

![]()

![]()