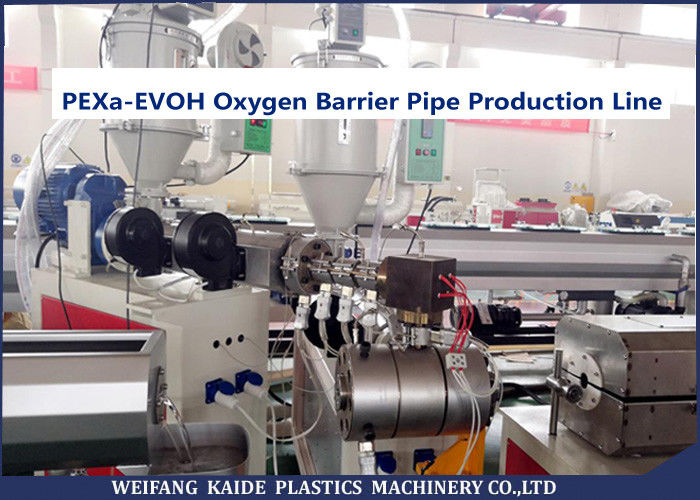

16 × 2.0mm PEXa EVOH Oxygen Barrier Pipe Making Machine

-

Product NamePEXa EVOH Oxygen Barrier Layer Coating Machine

-

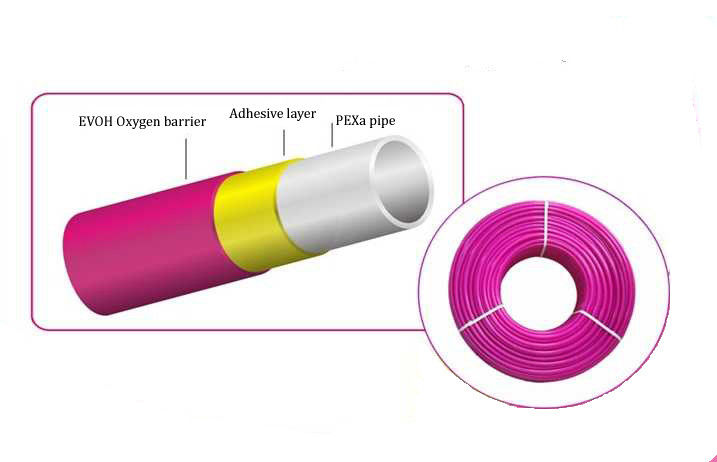

EVOH Pipe Type3 Layer PEXa/EVOH Pipe

-

Pipe Diameter16-32mm

-

Extruder NumberTwo Exturder For EVOH And Adhesive Layer

-

Die HeadTwo Layer Co-extrusion

-

Place of OriginWeifang, China

-

Brand NameKAIDE

-

CertificationCE; ISO

-

Model NumberEVOH pipe extrusion machine

-

Minimum Order Quantity1set

-

PriceNegotiable

-

Packaging Detailssoft film with sponge

-

Delivery Time60 working days

-

Payment TermsL/C, , T/T

-

Supply Ability200 sets per year

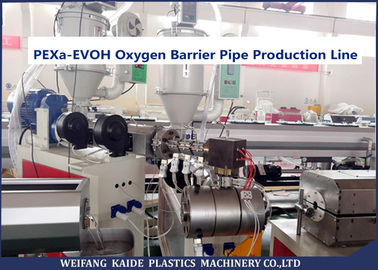

16 × 2.0mm PEXa EVOH Oxygen Barrier Pipe Making Machine

3 Layer PEXa EVOH Oxygen Barrier Pipe Production Line

EVOH oxygen barrier Coating Layer Making Machine

![]()

PEX-a EVOH Pipe: Suitable for underfloor heating systems and radiators.

Its manufactured by the peroxide xa cross-linking system. It has 3 layers: PEXa / adhesive / EVOH. The PEXa EVOH pipe has great flexibility and perfect homogenization of the cross-linking. It is very resistant to corrosion and chemical agents. It has an excellent thermal memory.

The EVOH barrier is a thin layer of ethyl vinyl alcohol that prevents the permeability of the pipe and diffusion of oxygen throught it. This avoids the corrosion of the metal parts, which prolongs the life of the whole installation.

Chemical resistance to building materials allows the PEXa EVOH pipe to be embeded in walls and floors without the need for protection.

![]()

| No. | Pipe Diameter | Pipe Thickness |

|---|---|---|

| 1 | 16mm | 2.0mm |

| 2 | 20mm | 2.0mm |

| 3 | 25mm | 2.3mm |

| 4 | 32mm | 2.9mm |

|

Design Features:

|

|

|

|

|

|

Design Features:

Tip and die mould surface are chrome-painted, to reduce friction force, increase its hardness and longer its service life, also easy to clean. |

|

|

Design Features:

|

|

|

Design Features:

|