Multilayer Automobile Fuel Tube Making Machine , 5 Layer Automobile Fuel Tube Making Machine

-

Product Name5 Layer PA Nylon Pipe Making Machine

-

Pipe Diameter6mm; 8mm; 10mm

-

Pipe MaterialNylone 12; EVOH, And Adhesive; 5 Layer Sturcture

-

Extrusion TechnologyMultilayer Co-extrusion Technology

-

Place of OriginWeifang, China

-

Brand NameKAIDE

-

CertificationCE; ISO

-

Model NumberEVOH pipe extrusion machine

-

Minimum Order Quantity1set

-

PriceNegotiable

-

Packaging Detailssoft film with sponge

-

Delivery Time60 working days

-

Payment TermsL/C, , T/T

-

Supply Ability200 sets per year

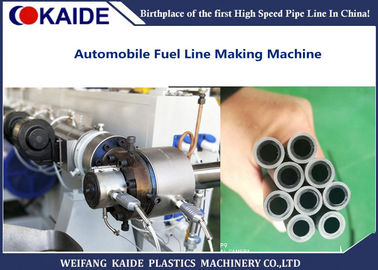

Multilayer Automobile Fuel Tube Making Machine , 5 Layer Automobile Fuel Tube Making Machine

5 Layer PA Nylone EVOH Oxygen Barrier Pipe Production Line

Multilayer Automobile PA Nylon Oil Tube Extrusion Machine

Below multilayer tube extrusion line is used to extrude 5 layer PA/EVOH automobile fule tube, with an outer diameter 6mm, 8mm and 10mm.

The PA multi-layer composite pipe can effectively reduce the automobile's emission pollution and meet higher enviromental requirements. As the multi-layer composite pipe features an excellent resistance to penetration, it meets EU-III standards.

Multilayer Pipe Structure:

- Inner layer: PA 12

- Inner adhesive layer

- EVOH oxygen barrier layer

- Outer adhesive layer

- Outer layer: PA 12

![]()

TECHNICAL DATA

| lINE Model | Screw diameter | Production Scope | Production Speed |

|---|---|---|---|

| KDFPA-45 | 45/45/30mm | 6-20mm | 40m/min |

| KDFPA-65 | 65/45/30mm | 6-20mm | 80m/min |

MULTILAYER AUTOMOBILE FUEL PIPE MACHINE

![]()

- Extruder is special designed for PA raw material, so that extrusion output and plastizizing quality are effectivly improved.

- Multilayer co-extrusion die head adopts special moulds steel, matching up with the unique multi-layer co-extrusion technology and high accuracy CNC processing to creat imcomparable features of high reliablity, usablility and high precision.

- Gravimetric material dosing system, thickness control system, and diameter measuring system are equipped to control produced pipe accuracy.

- SIEMENS PLC system to realize many inteligent operations, such as multi-machine linkage, sperate machine control, fault diagnosis, remote control etc. At same time, advanced on line nonitoring and control technologies, such as servo tracking technology, static digital filter technology etc, are used to ensure plastizing quality and produced pipe accuracy under high speed extrusion.

![]()

![]()

![]()

![]()

MORE INFORMATION NEEDED,

PLS CONTACT US RIGHT NOW!!